3D Fan Fold Ultimate Bipe and 3DX

by Tim Hart

Note: I got this email from Mike Hammel and liked his plane so much that

I asked him for permission to show it off here.

Read the Email below then proceed to the building sequence that follows.

| This is all the stuff you need to build your own small

electric 3d airplane. The plane is a foam profile plane that has 360 sq

in, 12 oz weight, will fly 15 to 20 minutes on one charge. It will do

all the 3d stuff and when you crash, it rarely gets hurt. I have been

flying flying 15 years and this is the most fun of any airplane I have

owned. You can fly it in a baseball diamond. It won't take allot of wind,

but it is great on those calm evenings when you don't have time to load

up the big stuff and drive to the field. Here we go; You can use two kinds of foam. Blue 1/4" foam (fan fold foam) or Depron foam. I used the fan fold foam. You get it at lowes or home depot. It is used to insulate basements before backfill. The fanfold foam cost about $25 for 50' x 48". That is enough for about 25 airframes! If you go with the dupron, do a google search to find sources. The fuse and wing will need stiffening rods. I used solid carbon fiber rods that I got from a local kite shop. Mine were 5/32 dia. The real secret is the power system: Go to www.allerc.com and order the GWS300 motor and D gearbox. This will give you 6.6 to 1 gear ratio. Order the Etec Li-Po batteries 1200 3s pack. This gives you about 12 volts at 1200MAH and weighs about 2.5 oz. You will need a special charger to charge the lipos, I used the Apache charger. The best prop is the GWS or Wattage 9 x 4.7. You will need to "re-time" the motor to get the most power and here is a thread to do that (it is easier than it looks). http://www.rcgroups.com/forums/showthread.php?s=6e0b111dcc8e8662d36b5bb625970a9c&threadid=97414&highlight=retiming Use whatever 15 amp speed control you want. I used the Wattage 15 amp because of its smooth control during hover. It does not surge the battery pack too hard and help extend run time The servos I used were the Hitec 55. The are hot glue mounted into the fuse. The receiver is also a lightweight unit that Hitec just came out with. It is a single conversion, so get the right crystal. The best place for hitec stuff is www.servocity.com. I used Tim Harts basic moments and methods to make my edge. It is easy to try different ideas. The best part is how cool it flies and when you crash, you don't hurt anything. I have attached a few shots of my own. YOU WILL HAVE A BLAST, I GARANTEE!!!!!!!!!!!!!!!!!!!!!!!! Mike Hammel 1704 Bullard Arkansas City, KS 67005 |

|

Well,

here's a review on my Fan Fold 3DX and Ultimate

Biplane. These 2 airframes are going to be built together and I'll

document the progress as it goes. Plans for both of these planes are

available for download.

|

|

Here

are links to the plans:

They are Zipped PDF files. 3DX-Plans.zip (tiled) 3dxPlans.zip (36" sheet) ultimate30inch.zip ultimate40inch.zip |

|

|

|

Carbon rod is glued into wing at the CG. I cut a 1/8" wide channel in the foam, then used the end of the tube to gouge out the channel to fit the tube. The carbon tubes came from a local kite store and are .11"x30" tubes. I used 30 min epoxy, but if you are a fast worker and have everything ready to go when you mix the epoxy, 5 min. stuff will work too.

|

|

The same method was used for the fuse. spar except I used 5 min. epoxy. Worked fine but you have to work quickly. The black printing comes off the Fan Fold very easily with a little denatured alcohol on a paper towel.

|

|

Motor mount was made from 3/8" square hardwood. I'm not sure what kind of wood it is, but it's fairly light hardwood.

|

|

Motor mount was grooved along the top side to fit the carbon rod. I carfully measured everything so the thrust angle would not get messed up (0,0 on proto) Then the motor cutout was made in the fuse.

|

|

Motor mount was epoxied to the carbon spar and the surrounding foam. I was very carefull to use just enough epoxy for what I needed. Weight of epoxy adds up fast.

|

|

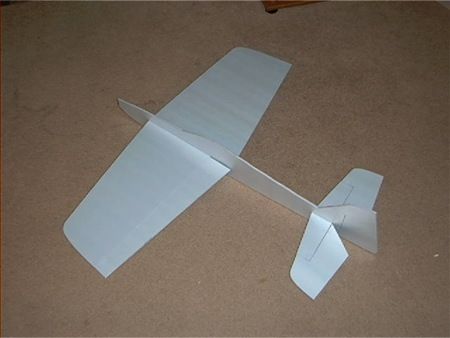

Airframe so far...

|

|

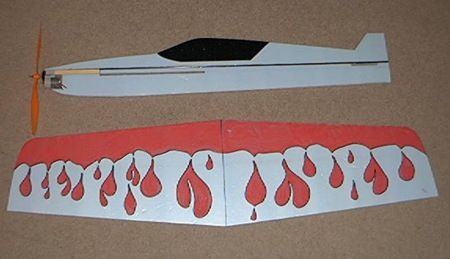

These are the paint pens I used for the colors. They are called "Permapaque" paint pens. I got them at the local Hobby Lobby Creative Center. They are not ink pens, but paint. They have a wide tip and a fine tip on each pen. They cover well, and dry fast. Best of all, I only added 1 gram to the wing after painting. These came in a pack of 4. I need to go back and see what other colors they come in. 4 colors doesn't cut it, but I didn't want to waste money if they didn't work out.

|

| Written by Tim Hart and Presented to you by Mike Hammel 7-22-2003 |

Check out Tim Hart's Website at www.foamyfactory.com